【旋启式止回阀描述】

- 1、旋启式止回阀的公称压力:1.6Mpa

- 2、旋启式止回阀的温度:-20℃~+110℃

- 3、旋启式止回阀的介质:水,非腐蚀性液体

- 4、旋启式止回阀的螺纹:BSP、NPT或其他客户指定

- 1、Nominal Pressure: 1.6Mpa

- 2、Working Temperature: -20℃~110℃

- 3、Working Medium: Water, non-corrosive liquid

- 4、Pipe thread: BSP、NPT or comply to customer request

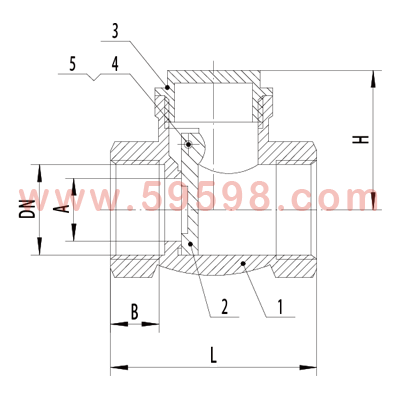

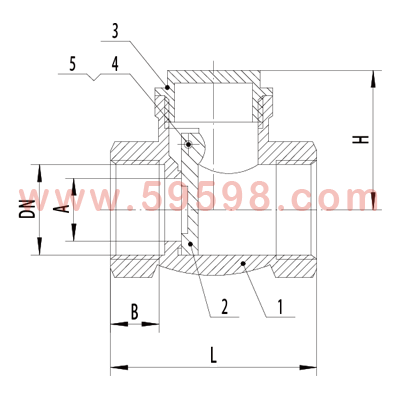

【旋启式止回阀注解图】

旋启式止回阀部件注解表:

部件标号

PART NUMBER |

部件名称

PART NAME |

材质

MATERIAL |

| 1 |

阀体 Body |

BRASS 黄铜 |

| 2 |

闸板 DISC |

BRASS 黄铜 |

| 3 |

Hinge Pin |

BRASS 黄铜 |

| 4 |

阀门螺帽 Valve Nut |

BRASS 黄铜 |

| 5 |

螺母 Screw |

BRASS 黄铜 |

【旋启式止回阀的安装指南】

1. 请确保阀门在合适的工况中使用。

2. 阀门安装前,请确保清除流体中的杂质, 否则可能造面密封面损坏。

3. 阀门安装前,务必先清除产品及阀门端面上的防护包装物。

4. 阀门安装时,请确保螺纹部分生带合理使用量,否则可能造成阀门与管道连接处泄露。

5. 阀门安装完成后,请确保连接管道没有对阀门形成拉伸,否则会造成对阀门螺纹的损坏。

6. 阀门投入使用前,请对管道进行压力测试以确保所有的连接处无泄露。

7. 阀门使用期间,请确保阀门打开与关闭的扭矩不应超过30Nm。

8. 请定期检查维护阀门,以确保阀门正常工作。

1.Please make sure that the valve is used under proper condition.

2.Before assembling, ensure removing impurities from the fluid which might cause the damage of the sealing face.

3.Before assembling, ensure removing all the packing material on both body and valve ends.

4.During assembling, ensure proper use of tape, otherwise it might cause the leakage of connection.

5.After assembling, check and ensure no stretch on the valve formed by pipeline which might cause the damage of thread.

6.Before valve using, operate pressure test of connection to make sure no leakage.

7.During valve using, make sure the torque of switch not over 30Nm.

8.Please verify the valves periodically to ensure all the application and function work correctly.

返回顶部

温馨提醒:旋启式止回阀是止回阀中的一款,主要功能是用来防止管路中的介质倒流,旋启式止回阀只用于介质单向流动的管路上,阻止介质回流,以防发生事故如对旋启式止回阀信息还不够了解可点击阀门仪表栏进行查询其他款式闸阀或咨询我们销售客服!

|